What Is Industrial Racking And How Could It Help Your Business?

Industrial or warehouse racking are generally also known as shelving storage systems designed to store and organize the products in an arranged manner. The availability of industrial racking brings thousands of benefits to businesses whether it’s about maximizing utilization of space or improving warehouse safety. It’s the backbone of any efficient warehouse and distribution centre.

Industrial racking has gained popularity due to the strong versatility and availability of holding more stock. As a result, it’ll help your business meet customer demand.

Sometimes, a warehouse can’t function properly due to improper management and poor arrangements of products. From up-to-date stock lists to a dedicated team of workers, it’s necessary to have everything well-structured and organized to streamline different processes smoothly and work efficiently. In the absence of imperative tools and a professional team, a manufacturer or supplier business would struggle to walk along with customers’ requirements and stay ahead of their competition. Do you want to know – how industrial racking is helpful for business Let’s find out!

What is Industrial Racking?

As the demand for online shopping is increasing day by day, the appropriate availability of storage space becomes a necessity for many organizations. Over the years, industrial storage racking systems become versatile, dynamic and adaptable systems for many businesses. So, what is exactly industrial racking?

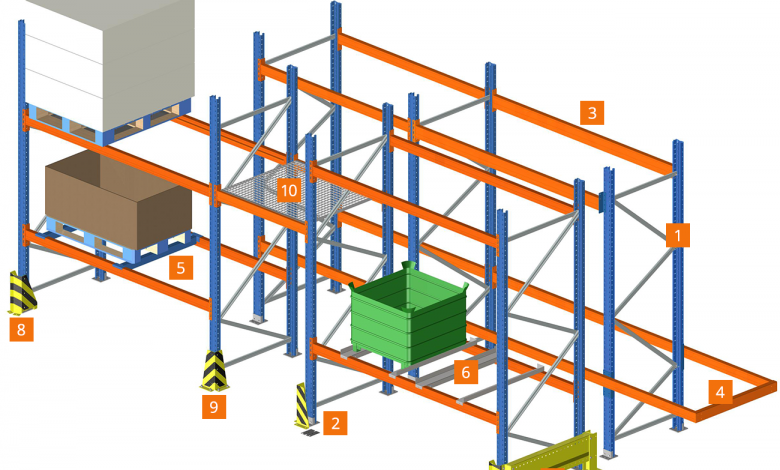

Generally, industrial racking is a material handling structure or storage system effective for storing different items or products in a warehouse or industrial facility. There are different types of industrial racking systems popular for maintaining smooth functioning in a warehouse. It plays a significant role in logistics and supply chain organizations.

Well, racking systems stores the products in horizontal rows on multiple vertical levels. The overall aim of installing such racking systems is to enhance the storage facility in a warehouse. These structures properly cover the unused space of a warehouse, such as vertical space.

Warehouse storage racking systems can effectively use the wasted vertical space to improve the overall structure of a warehouse. For accessing the palletized materials, warehouses use forklift trucks to load and unload the materials from on and off the rack shelves. It will increase warehouse efficiency and save stock-picking time.

How Industrial Racking Systems are Great for Businesses?

Optimization of Warehouse Space

Installing racking systems implies maximizing the storage capacity of a warehouse in vertical terms. Generally, warehouses contain a significant percentage of unused vertical space. Installing pallet racks in such empty floor space can effectively offer maximum square footage. Additionally, the availability of racking systems provides enough safe passage and access to forklifts in the aisles. So, let’s think about making proper utilization of space through racking systems.

Fulfil Bulk Storage Needs

Warehouses that deal with massive inventory needs, but have fewer SKUs (Stock Keeping Unit), can fulfil their requirements by installing different pallet racking systems. Some racking systems, including push-back pallet racks, pallet flow racks, and drive-in or drive-thru pallet racks can store a high density of product SKUs.

Each system has its own advantages and properties designed for specific areas of necessity. These systems provide enough space for storing bulk products in each row, reducing the number of aisles required to reach the product further increasing storage capacities. For example, a drive-in or drive-thru storage racking enhances accommodation capacity by 7 times and 3 times compared to the other pallet racking systems.

Proper Inventory Control Management

Each inventory has different requirements and needs a different approach to handle them. Let’s take an instance, your warehouse has nearby and farther expiration date goods. However, proper inventory management means not storing such goods together as it creates confusion. It is where the racking storage system plays a significant role in managing your inventory flow.

And push back pallet racks are an excellent way to store multiple pallets in the same pallet compartment. Each compartment has a roller system, which is angled towards the front of the rack. Whenever a new pallet is added to the compartment, it pushes the already existing pallets to the front. Likewise, when a pallet is removed, the remaining pallets come at the front ones. Such systems are an effective choice to store multiple pallets as they work on the principle of Last in, First out.

The market is also fully-fledged with such racking systems that work on the policy of First in, First out. In this, a pallet rack is loaded from one side and unloaded from another. Hence, the choice of industrial racking systems depends on your business requirements.

Read more business Blogs here.

Optimize Warehouse Safety

The effective benefit of installing the pallet racking system is to obtain and enhance the overall warehouse safety. Whenever you work according to the safety standards, it’ll automatically create an improved and safe environment for employees and stored products. Being a warehouse owner or manager, you might also have to consider some safety constraints, such as load weight, forklift operations, height restrictions, and worker logistics.

Taking into consideration all the appropriate logistics will conveniently increase warehouse safety. Custom-designed pallet racks can absolutely satisfy the height and weight capacity requirements due to their sturdy and reliable structure. However, don’t forget to consider the forklift operations while installing a new storage rack system. Things like height and load constraints will impact your safety considerations. So, be aware of every aspect and also determine the upcoming obstacles that might affect the height and weight of a racking system.

Wrapping Up!

It doesn’t matter which storage racking you’re going to give preference. The foremost thing that matters while choosing a racking system is proper planning. Each warehouse has different requirements and contains different products. A Pallet rack system helps to handle bulk products and enables you to stack products on pallets for more efficient storage and automation.

Hence, it’s advisable to find out your business requirements to accommodate different merchandise. Additionally, using forklifts provide a safe way to organize and access your facility.