Don’t know how to install or plumb a Pex Water Supply System? If yes, then you are in right place.

In this post, we are going to share with you the amazing 5 steps to Plumbing a Pex Water Supply System:

5 Steps to Plumbing a Pex Water Supply System

Below given procedure help you to Plumbing a Pex Water Supply System:

Step 1

Install copper manifolds (one for hot and one for cold) in an accessible location central to the fixtures. The manifold should have one outlet for each supply line it will support (fixtures that require hot and cold supply will need a separate outlet for each). Run supply lines from the water heater and water main to the copper manifolds. Connect the supply pipes to the manifolds with crimp fittings.

Step 2

A manifold may be attached vertically or horizontally, but it must be anchored with correctly sized hangers screwed to the framing members.

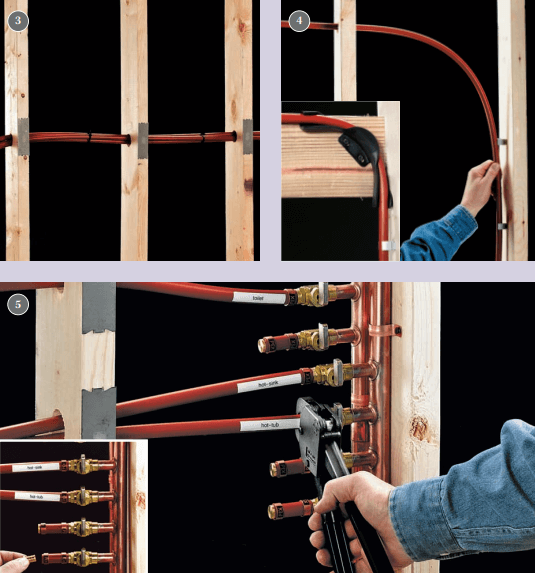

Step 3

Starting at each fixture (and leaving at least 12″ of extra pipe exposed), run appropriately sized PEX through holes in the framing to the manifolds. Pipes may be bundled together loosely with plastic ties. Protect the line with a nailing plate at each stud location. Be sure to leave some slack in the supply lines. Before reading more steps, if you are looking for Pipe Relining Service in Sydney then contact your nearest specialist.

Step 4

Support the pipe with a plastic hanger near every floor or ceiling and midway up vertical runs. Also, use hangers to guide pipe near the beginnings and ends of curves and near fittings. Use a plastic guide for sharp curves (inset). Do not bend PEX so sharply that it kinks.

Step 5

Cut each branch supply line to length (leave some extra in case you need to scrimp). Install shutoff valves for each outlet (most manifolds come with preattached valves). Connect the PEX branch supply lines to the shutoff valves. Label each pipe. Use a short length of PEX and a plug to seal any unused outlets (inset).

The PEX Plumbing Design Guide provides the information and resources necessary to design and install cross-linked polyethylene (PEX). Also, let’s win a war with Pests.

How to make PEX Connections?

- Cut the pipe to length, making sure to leave enough extra material so the line will have a small amount of slack once the connections are made. A straight, clean-cut is very important. For best results, use a tubing cutter.

- Inspect the cut end to make sure it is clean and smooth. If necessary, deburr the end of the pipe with a sharp utility knife. Slip a crimp ring over the end.

- Insert the barbed end of the fitting into the pipe until it is snug against the cut edges. Position the crimp ring so it is 1⁄8″ to 1⁄4″ from the end of the pipe, covering the barbed end of the fitting. Pinch the fitting to hold it in place.

- Align the jaws of a full‑circle crimping tool over the crimp ring and squeeze the handles together to apply strong, even pressure to the ring.

- Test the connection to make sure it is mechanically acceptable, using a go/no‑go gauge. If the ring does not fit into the gauge properly, cut the pipe near the connection and try again.

How to Choosing a PEX System?

- For maximum single‑fixture water pressure: Trunk and branch

- For economy of materials: Trunk and branch or remote manifold

- Minimal wait times for hot water (single fixture): Home run

- For minimal wait times for hot water (multiple fixtures used at the same approximate time): Trunk and branch or remote manifold

- Ease of shutoff control: Home run

- For the lowest number of fittings and joints: The home run

PEX advantage

PEX supply tubing offers a number of advantages over traditional rigid supply tubing:

- Easy to install. PEX does not require coupling joints for long runs or elbows and sweeps for turns. The mechanical connections do not require solvents or soldering.

- Easy to transport. Large coils are lightweight and much easier to move around than 10‑ft. lengths of pipe.

- Good insulation. The PEX material has better thermal properties than copper for lessened heat loss.

- Quiet. PEX will not rattle or clang from trapped air or kinetic energy.

- Good for retrofit jobs. PEX is easier to snake through walls than rigid supply tubing and is compatible with copper, PVC, or iron supply systems if the correct transition fittings are used. If your metal supply tubes are used to ground your electrical system, you’ll need to provide a jumper if PEX is installed in midrun. Check with a plumber or electrician.

- Freeze resistant. PEX retains some flexibility in sub‑freezing conditions and is less likely to be damaged than the rigid pipe, but it is not frostproof.

Thank you for reading an article on Plumbing a Pex Water Supply System. Furthermore, if you have any questions regarding PEX System then please do comment below.